Task Canvas- a Powerful Tool for Controlling Lathe Automation

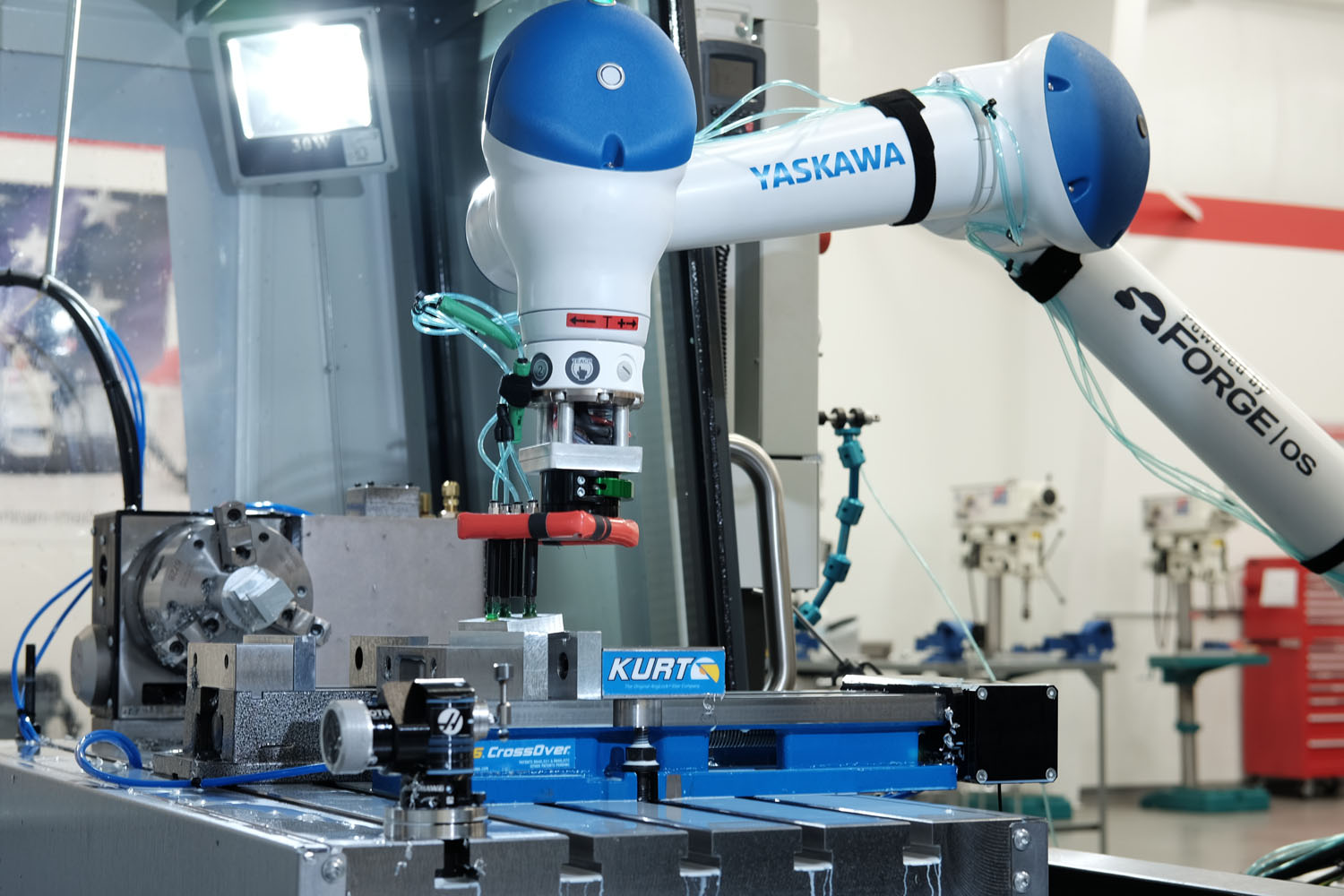

Task Canvas, READY’s user-friendly touchscreen programming software controls the robot arm and the other actions in the workcell. Task Canvas, empowers anyone to implement and maintain lathe automation programs.

The Grid block is used to accurately map the layout of a grid of parts. The robot arm is directed to pick from each location. Task Canvas assists in calculating the grid's dimensions and part locations.

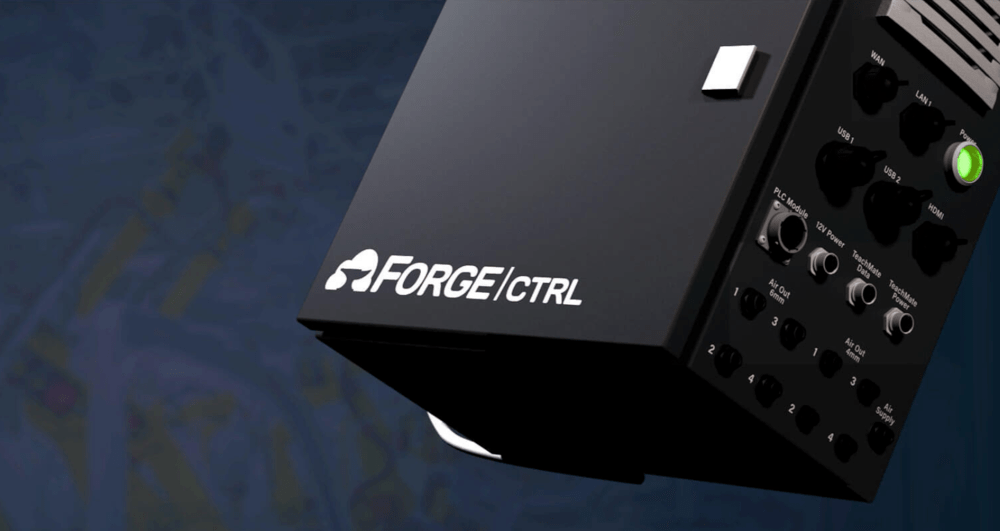

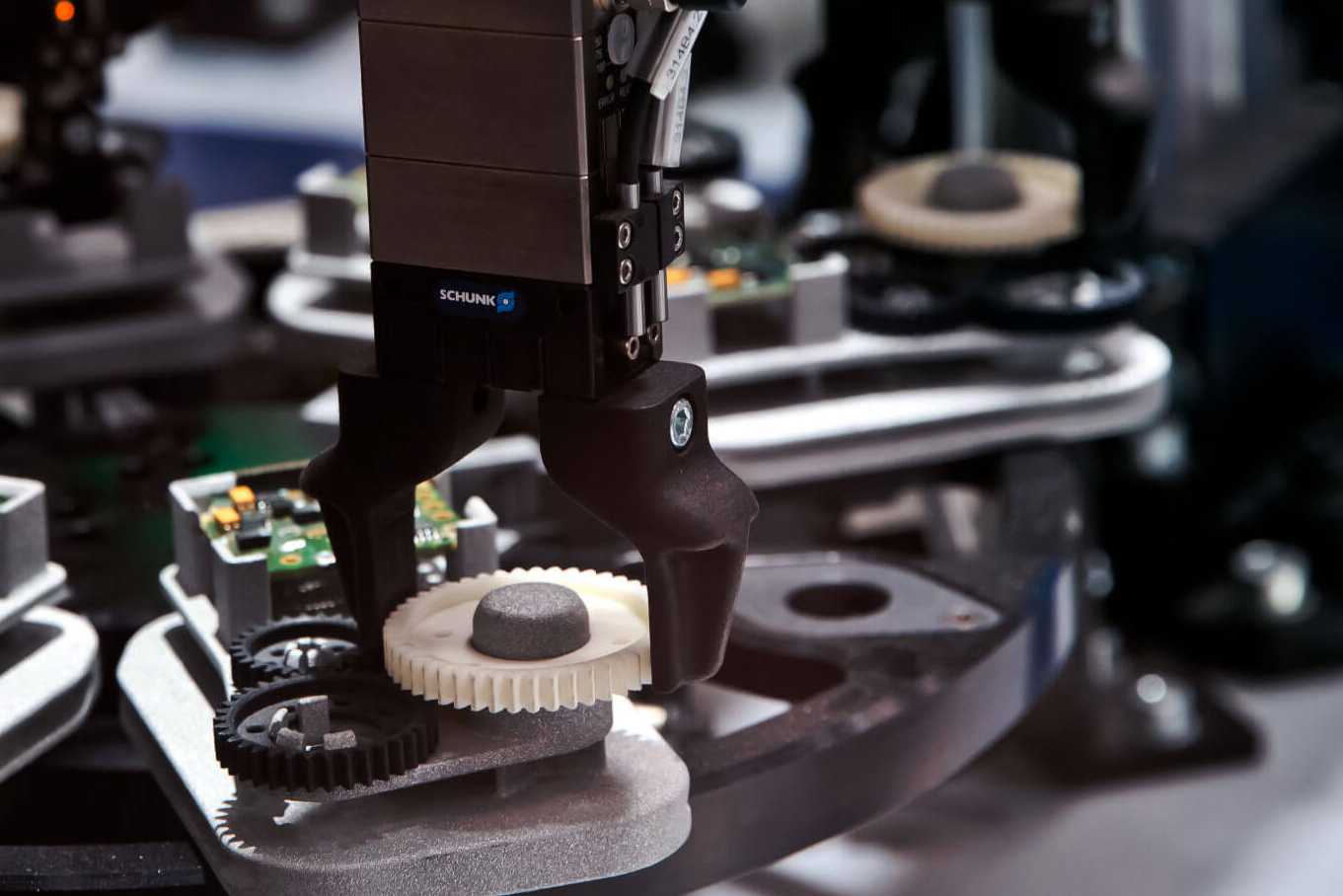

Gripper blocks can be used to open and close a robot's end of arm tooling (EOAT), which is useful for picking up and placing parts. Forge/OS can be configured to operate both electronic and pneumatic grippers.

The Blend Move block can be used to perform complex movements quickly and fluidly and prevent collision as you enter and exit your machine tool.

The Jog block can be used to move the part in and out of the workholding precisely. This allows for the part to be placed in a repeatable location inside the machine, resulting in high-quality, finished products.

Forge/OS is equipped with reading and writing input/output (I/O) signals. If the CNC lathe is equipped with I/O, then Forge/OS can directly communicate with the lathe. This reduces cycle time significantly.

Pneumatic Control Blocks can be used to actuate pneumatic devices within a workcell. The READY Pneumatic Button Actuator, and the READY Pedal Actuator, can be mounted on the CNC Lathe and actuated when the procedure requires the press of a button to start a cycle or when a task requires a pedal press to begin a cycle or actuate your workholding.

The Counter block can be used to define how many times a specific action is carried out. This is useful when determining when a load of parts is complete based on how many times a cycle has run.

The Breakpoint block stops the robot and notifies the operator by emailing them a customizable message. Breakpoint blocks are useful for communicating when to load more unfinished parts into a workcell.

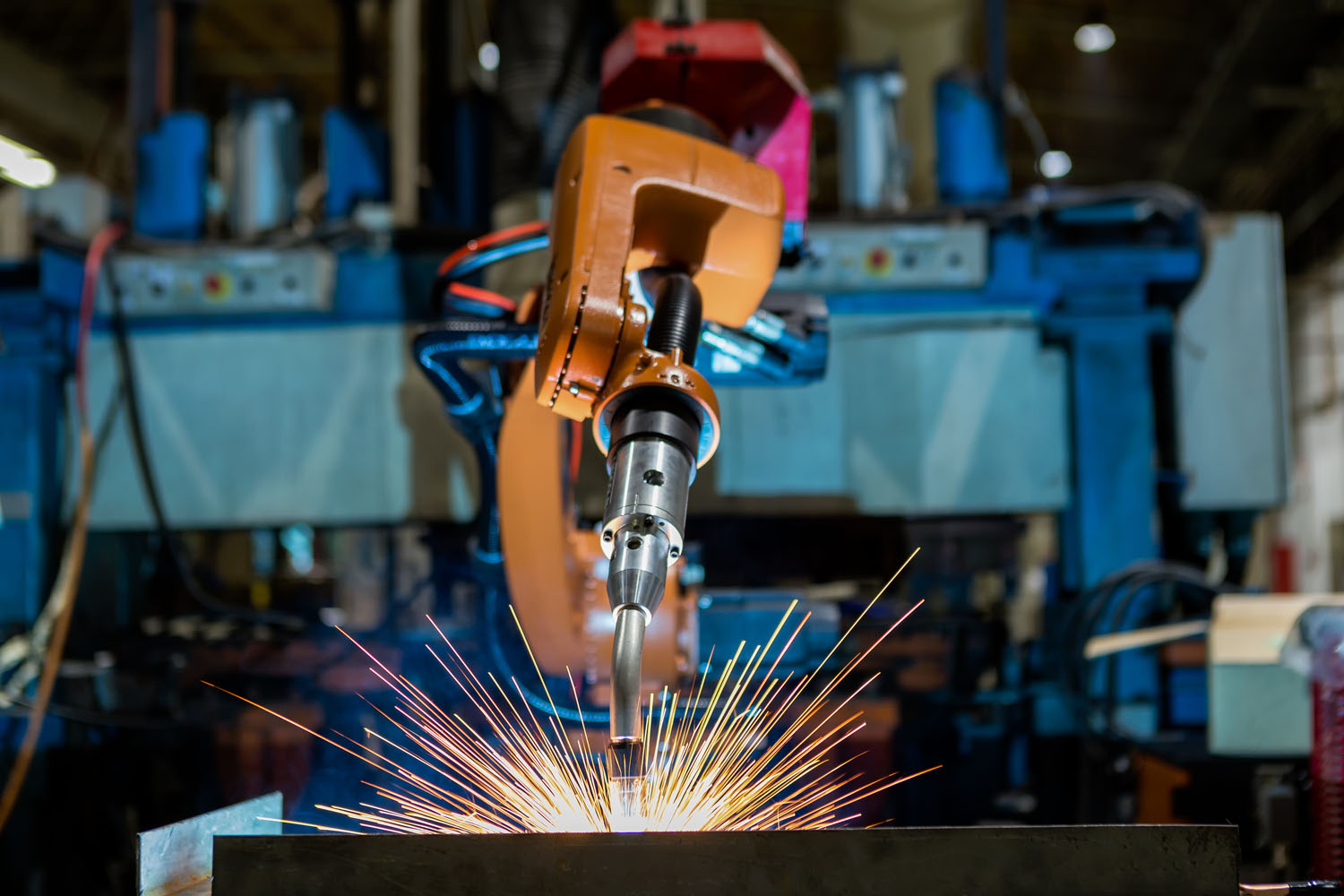

Our automation experts are ready to help you determine the right automation solution for your production environment.

CNC Lathe Automation Guide

Learn the requirements for automating a CNC lathe, techniques for connecting and controlling the components of a CNC lathe workcell, as well as safety considerations and programming tips that will reduce deployment time.

Deploy in Hours or Days

Traditional automation takes weeks or months to deploy. READY Automation Packages powered by Forge/OS typically take one day to automate a lathe.

Easy to Automate

Task Canvas is so easy to learn and use, that most are comfortable programming complex tasks in just a few hours - even with no prior robot programming experience.

Accelerate Changeover

Easily control all aspects of your automation process. Quickly program new tasks, or modify current tasks for parts changeover. Reduce programming task time by 80% with task templates.

Stanley Black & Decker

"Couple the ease of setup with capable performance and we can achieve an ROI in less than two years

on this first application alone."

-Jim Olsen, Manufacturing Engineering Manager

Stanley Black & Decker pilot facility

In our CNC production department, we’re expecting about a 50% reduction in labor costs associated with manufacturing products.